Returns are a fact of life in the multichannel retail world, and reverse logistics is a crucial and growing part of the supply chain process. Yet many companies fail to measure their returns process with the same rigor they use for outbound distribution.

Why do customers return goods? The Supply Chain Consortium’s recent Distribution Center Operations Report and the earlier Reverse Logistics: Returns, Refunds and Recalls Hot Topic Report revealed THE TOP SIX REASONS FOR RETURNS:

- The customer ordered incorrect product or size

- The customer decided the product was not needed or wanted

- No reason for return given

- The product did not match the description on the Website or in the catalog

- The product did not fit the customer’s expectations

- The company shipped the incorrect product or size.

Note that only the sixth reason is clearly an error made by the company. The Supply Chain Consortium’s reports aimed to uncover how well companies plan their returns processes, the systems they use, who pays for transporting the returned product, and what credit options companies allow, among other factors.

Below are some findings from the reports and further insights that may help you determine how your company measures up in regard to reverse logistics.

- Internet and catalog sales have a higher percentage of returns than do sales through standard distribution channels.

- More than half of the survey respondents request feedback from customers on their returns process. Most don’t feel good about what they learn.

- Less than half of the companies surveyed require pre-approval for a return.

- Warehouse management systems are the most common systems used for returns processes, although many respondents use more than one system.

- Responses for the “ship-to” locations for returns are different for retailers than for manufacturers. Retailers are more likely to ship returns to a company-operated facility or store, while manufacturers have them returned to their fulfillment centers.

- Retail companies are likely to pay for returns transportation, while manufacturers most often expect the customer to pay.

- Events that trigger a refund or credit and the time interval from receipt to refund or credit vary greatly by company and industry. But nearly 60% of all companies issue refunds or credits within 24 hours.

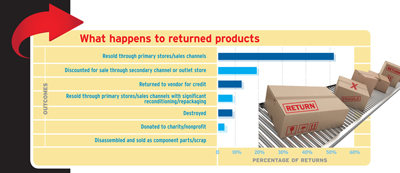

- The most common disposal methods for returned products are reselling through the primary channel, discounting through a secondary channel, or returning the product to the vendor.

- Recycling of products leads the list of environmental concerns with respect to returns processing.

- There is no great indication of which department or organization owns returns, and the position level responsible for returns varies by company size.

REDUCING RETURNS

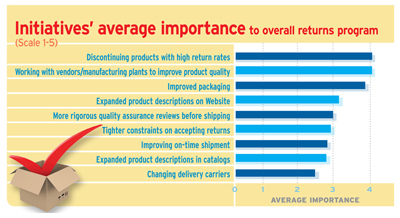

Every merchant wants to cut down on returns; following the industry’s best practices can help. For instance, you have to understand the metrics of the returns process, and measure and continuously improve processing performance.

You should also review company returns policies and customer service practices to look for ways to reduce returns. And you can use information technology to track and monitor the process and provide information on returns to the rest of the organization.

A few other things you can do:

- Organize for returns processing and development of efficient practices.

- Provide adequate physical facilities and resources.

- Improve product quality and packaging.

Overall, companies need to focus on their returns policies and customer service, information technology, markets and speed, physical facilities and resources, as well as product quality and packaging.

To successfully manage reverse logistics, you must pay attention to all the aspects of the returns process just as you have for the forward process. You can’t simply just run the process in reverse.

Bruce Tompkins is executive director of The Supply Chain Consortium (www.supplychainconsortium.com), a source for supply chain benchmarking and best practices knowledge.