In a world of constrained resources, companies can no longer rely on a one-size-fits-all approach to order promising and fulfillment. Instead, companies need to establish a system that respects the priorities of its various products and customer segments.

Just as each product has a different cost/margin potential associated with it, each customer segment has a different cost to serve/profitability impact associated with it. Depending on an enterprise’s strategic objectives — such as increasing market share, revenue, margin, etc. — it needs to segment product and customer portfolios based on established priorities and ensure that these priorities are followed when fulfilling orders.

To give you a better idea of how this works, a world-class order fulfillment process and system should exhibit the following traits:

- A hierarchical allocation of supply that respects customer priority and the demand forecast

- Real-time order promising and supply pegging (assignment) to an order

- Optimal re-balancing when supply changes

There are two goals to keep in mind when establishing a world-class order promising process and system: reliable promising and profitable promising. Reliable promising, commonly known as “Give a date, keep a date,” is the process of assigning a ship date and then shipping the product on that day. Profitable promising involves determining the optimal trade-off between the cost to serve the customer and the customer value proposition (such as lower price, immediate availability, or customization options).

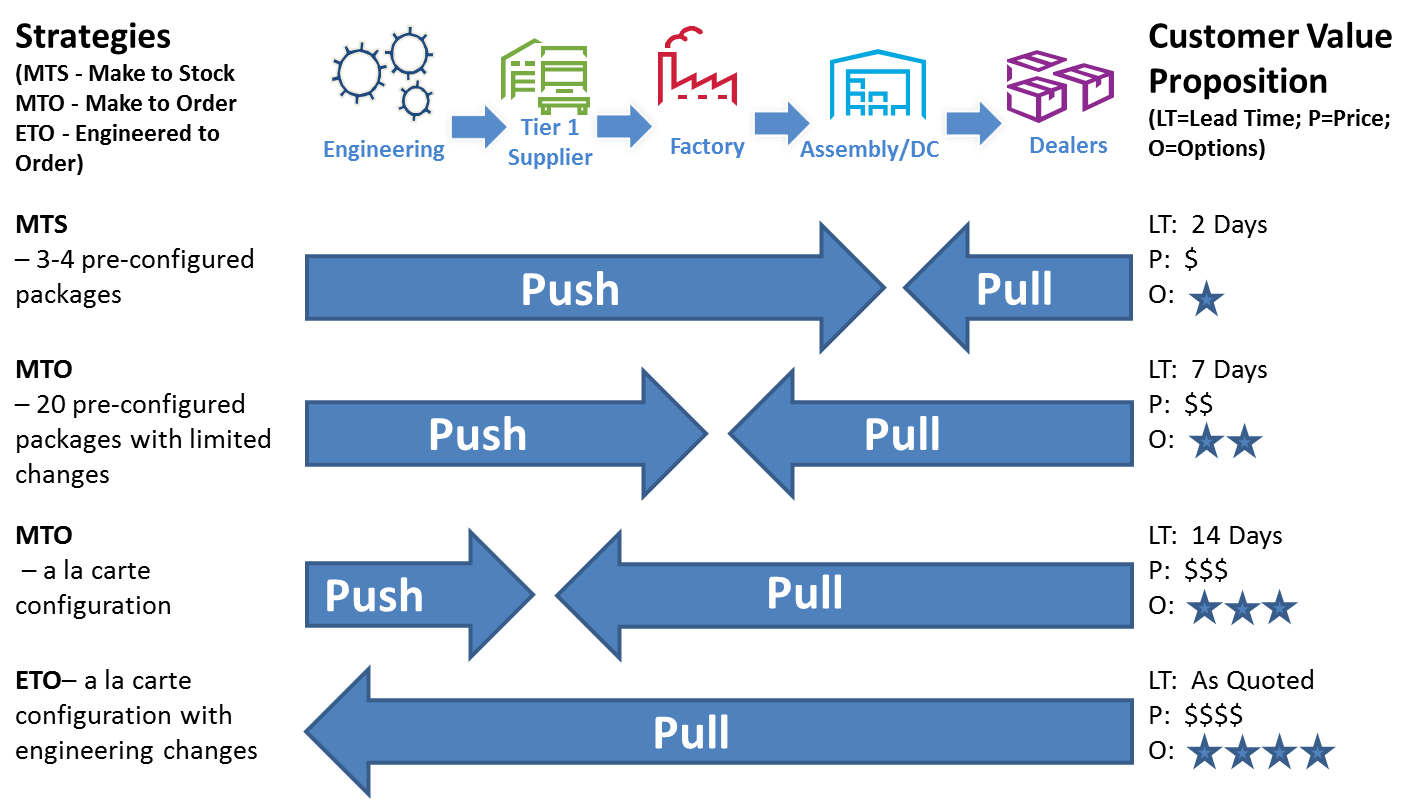

For instance, say you have a product for which a certain customer segment is willing to pay extra if it is readily available, whereas immediate availability doesn’t matter to another customer segment. The order promising system needs to offer zero lead time to the first customer segment and an extended lead time to the other. To view a potential fulfillment strategy based on different customer value propositions, see Figure 1.

Figure 1: Fulfillment strategies aligned to customer value propositions

Figure 1: Fulfillment strategies aligned to customer value propositions

Establishing this type of structured — and profitable — fulfillment process involves these three steps:

Allocate the available to promise supply

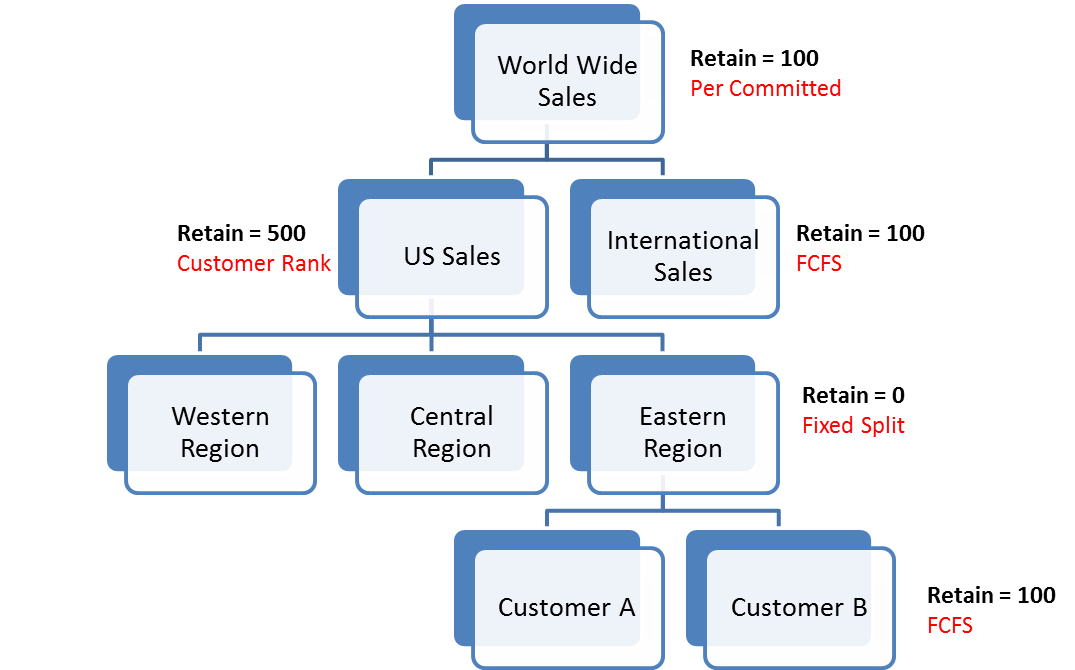

When doing so, you need to take into account customer priority and your demand forecast. Many enterprises follow the rule of “No forecast, no allocation,” which means any orders that aren’t forecasted automatically receive the least priority. This policy also serves as a catalyst to prompt the sales force to timely enter the forecast and not wait until the last minute. However, for most companies, the allocated supply hierarchy looks more like Figure 2.

In this example, if an order of 120 comes from Customer A, 100 will be fulfilled from Customer A’s allotment and 20 will be fulfilled from the U.S. Sales allotment. This process ensures that Customer B always has a minimum allotment of 100, no matter how many orders come in from Customer A. This enables you to guarantee a certain service level to your preferred customers.

Support real-time order promising and supply pegging

Very often, customers have a batch promising process that accumulates all of the orders that come in over the course of a day, which are then processed nightly. This creates latency not warranted in today’s high-powered computing world. Real-time order promising requires a seamless interface between the order capture system and the underlying promising engine.

Re-balance when supply changes

One of the goals of a world-class order promising system is a reliable promise. Promises are made based on assumptions of what is on hand, what is on trucks, what is scheduled for production and so forth. When disruptions happen (such as a factory outage or a truck breakdown), the supply assumptions are no longer the same. If this happens, the system should programmatically re-promise the orders based on the new supply assumptions. The re-promise should result in minimal changes to the original promise dates, yet maximize profitability.

To maintain profitability while ensuring service level to your preferred customers, focus on establishing an order fulfillment process and system that features these three traits: hierarchical supply allocation capabilities; real-time integrated order promising; and optimal supply re-balancing capabilities. Most companies have experienced an average service level gain of 15-25 percentage points after adopting a best-in-class order promising process and system. Additionally, service level improvements result in increased customer loyalty, and often an increase in top-line revenue.

Amitabh Kumar is Industry Strategies Director, Manufacturing, JDA Software.