In performing operational assessments for multichannel companies and identifying ways to improve storage capacity and increase order throughput, one of the major alternatives to opening a new ecommerce fulfillment center is adding mezzanines.

Planning and opening a new FC is expensive when you consider the capital investment and one-time expenses. It can take 12 months or longer, even assuming you find an existing facility that meets your requirements. If it’s more than 30 miles from your existing FC – which is usually the case – you’ll lose hourly workers and some managers.

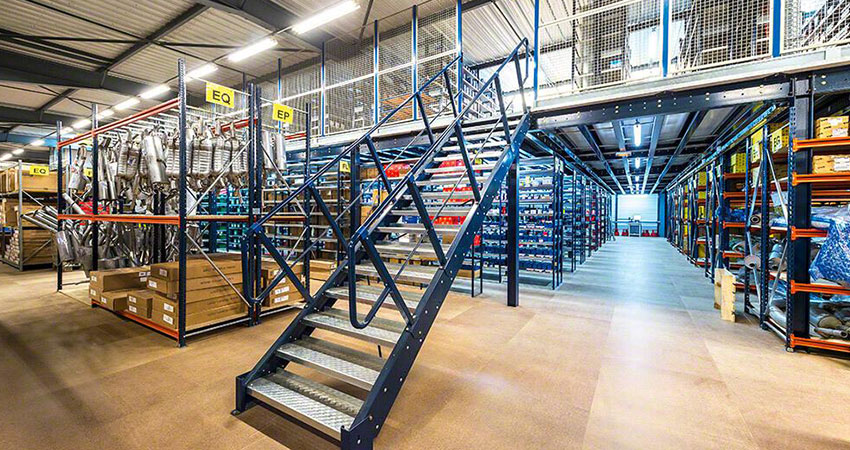

A mezzanine is a structure installed above an existing work area to increase space. It can go over low-height operations such as shipping and receiving. Functions we see implemented on mezzanines include:

- Automated pick modules

- Product storage

- Offices

- Outbound shipping and manifesting stations for various carriers

- Specialized work platforms

- Catwalks over highly automated sortation lines for visibility

As you explore adding mezzanines to your ecommerce fulfillment center, here are 12 points to consider:

Establish the Objectives

Detail your design objectives, including changes in product flow, automation and conveyors. Projects that involve adding storage and processes to mezzanines often mean big changes to product flow and the addition of conveyors and material handling equipment. It needs to make sense from all those perspectives, so you should think out the changes and design.

Here is a case study where adding a mezzanine and conveyors did not make sense. A gift retailer we work with added 25,000 square feet of mezzanine space for storage of lightweight fragile products (figurines, China, stemware, etc.). Orders were picked to carton and put on a spiral conveyor to packing and shipping areas below.

About every 10 cartons gained too much momentum from the spiral conveyor, fell off and broke. The conveyor had been designed too tight to allow for maximum square footage in the mezzanine. After numerous modifications the problem was minimized. Look to the vendors to certify the design objectives.

Working with Your Landlord

If your business is in a leased facility, it’s not uncommon to gain permission for adding a mezzanine. Your company may have to pay for the investment in total or on a shared basis.

Understand State, Local Building Codes

As you define your fulfillment objectives and the use of mezzanines, consult county officials early on in the process. Most have regulations about how mezzanines can be used. Some states define work platforms differently than mezzanines. They may dictate what operations and products can be stored on mezzanines. Also, the county will most likely have fire protection and safety regulations your project must address. Do this early so you know the code requirements.

Develop a Project Plan

Ask the vendor to develop a detailed work plan and schedule. Generally, mezzanines can be installed in 9-12 weeks from project signoff.

Integration to Building Design

Will the mezzanine design drawings be integrated with the CAD drawings of the building?

Multi-Level Operations

What material handling equipment and automation is required to move product and orders between levels? What changes to lighting and fire protection have to be met with multiple level operations?

Project Management

Identify which party will take responsibility for project management. Is it the vendor installing the mezzanine, your senior fulfillment manager or a fulfillment consultant?

Floor Strength

You need to conduct core sampling to understand how much weight from additional steel and concrete can be supported by the existing floor – when will this be done? What additional structures and materials are needed to support the mezzanine?

Installation Methodology

How will the installation process proceed? How will you keep operational disruption to a minimum?

Other Concerns

What safety measures and insurance are required? Considering the mezzanine, how many footsteps are needed for associates to get on and off it? What local approvals and inspections will be necessary?

Total Project Cost

Request the total cost for design and drawings, accessories, freight, steel surcharges and installation. With some projects and companies, steel surcharges are added. You’ll want to clarify if any surcharges are expected before ordering, their costs and what they represent.

The RFP

After you have defined your objectives, write an RFP that itemizes these considerations and identify several qualified bidders. Request an onsite visit before proposal submission to be sure they fully understand the project.

Ask the vendor to list mezzanine dimensions, load capacities, electrical requirements, bracing styles, coatings and finishes and accessories such as stairs, gates and handrails. You’re not looking for simply a cost proposal but a well-thought-out plan that includes the total investment and how it will benefit your operation.

Mezzanines can often add product storage capacity, increase order processing capabilities and extend the life of your existing ecommerce fulfillment center. It can save on capital and be stood up much faster than moving to a new warehouse.

Brian Barry is President of F. Curtis Barry & Company