Gap Inc. turned a disastrous event – a devastating August 2016 fire at its distribution center in Fishkill, NY – into an opportunity to improve its overall supply chain operations, an executive told attendees at Parcel Forum in Chicago.

“It was a very tough time,” said Kevin Kuntz, senior vice president of global logistics operations for Gap Inc., who works of the company’s facility in Gallatin, TN. “We literally set up a remote command center in Nashville that night. We started work on the business continuity plans we’d practiced a lot. People think they’ll never really need this, I was definitely one of those folks who though that way.”

Half a million square feet of the DC burned down, and another 500,000 square feet was damaged by smoke, but it was in a far end of the facility and amazingly no one was missing or hurt.

Kuntz said Gap Inc. was able to keep its operations up and running that fall and into holiday peak through a combination of diverting volume to its other main hubs in Gallatin and Fresno, CA, hundreds of additional hires, support from vendors and even competitors coming to the company’s aid by lending the use of their facilities.

The situation also revealed a ton about the quality of Gap’s fulfillment workers, Kuntz said.

“You learn there are some people who run to the crisis, and thankfully we had lot of them, working 12-hour days,” he said. “Some run away because it’s just too much work, so we were able to separate teams into those that produce and those that don’t. Fortunately for us the majority ran to the crisis and dug in. We managed to service our customers that holiday. This was an online facility, two months before the height of peak season.”

Kuntz said Gap Inc. was already on a path to reinventing its supply chain to meet the demands of an omnichannel world; the Fishkill fire just ratcheted up the urgency.

“One of the drivers is, how tight the labor market is,” he said. “As the industry goes through a transformation with more volume in ecommerce, the people need (for fulfillment) is five times retail. So how do we slow it down? Through investment in technology, reallocating people and teaching them to work with robotics and AI.”

One of the main takeaways from the experience, Kuntz said, is that Gap Inc. showed that the common business wisdom that a large company can’t pivot as quickly as a hungry startup isn’t always true.

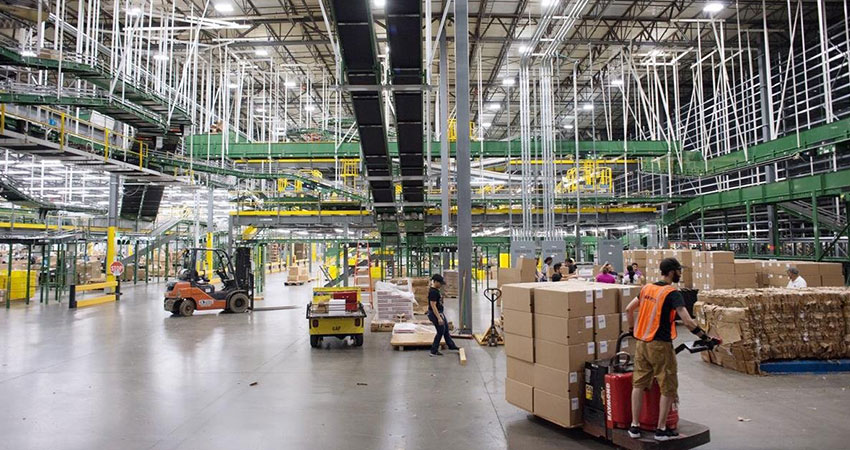

To that point, he said the highly automated facility in Gallatin – including robotic arms handling item sortation – was designed and built in less than a year. Gap Inc. has been ramping up volume since the facility opened in 2017, simulating peaks and identifying and overcoming pinch points. Now it’s able to handle up to 500,000 items a day, a throughput capability that will be put to the test this holiday season.

“Scale for us was an advantage,” he said. “They say you’re too big to be nimble, there’s no way you can innovate. We were on a journey pre-fire to do just that, we were becoming more efficient, responding to the labor shift. We found through the fire and the challenge that our scale actually was something to be celebrated. It allowed us to do things other folks couldn’t do.”