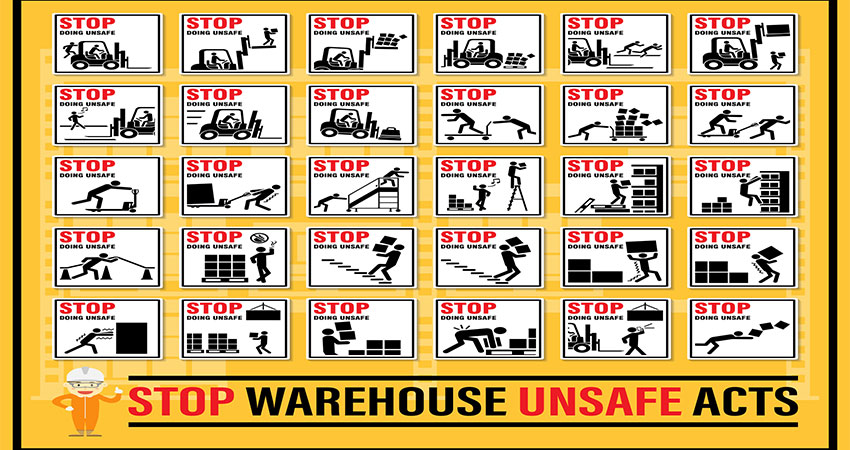

With constant incoming product, replenishment, picking and shipping, the typical ecommerce fulfillment center is a beehive of activity. When you add seasonal employees for the peak, the activity and the potential of injuries goes up dramatically.

OSHA has published a 26-page pocket guide on warehouse safety which we have found useful for clients that are reviewing workplace safety practices and policies.

To assist you in thinking about how to improve your facility’s safety, we have selected some of the more common causes of injuries. We offer our insight and recommendations as well as those in the pocket guide.

Forklift Accidents

The OSHA Pocket Guide says, “About 100 employees are killed and 95,000 injured every year while operating forklifts in all industries. Forklift turnovers account for a significant percentage of these fatalities.”

Here are the OSHA solutions:

- Train, evaluate and certify all operators to ensure that they can operate forklifts safely

- Do not allow anyone under 18 years old to operate a forklift

- Properly maintain haulage equipment, including tires

- Before using a forklift, examine it for hazardous conditions which would make it unsafe to operate

- Follow safe procedures for picking up, putting down and stacking loads

- Drive safely, never exceeding 5 MPH, and slow down in congested areas or those with slippery surfaces

Falling Objects

Stacking products high is a great way to effectively utilize space in your ecommerce fulfillment center, but it can also create hazards in the form of falling product. Whether it’s sloppily stored merchandise or odd-shaped product, it’s important to stack smart.

Prevention: The heavier the load, the more care required when stacking. Pay special attention to cylindrical objects which can easily roll off shelves and cause serious injury.

Slips, Trips and Falls

One of the major causes of ecommerce fulfillment center injuries is clutter causing tripping and slipping hazards in aisles and walk paths. As we walk through facilities we often see broken pallets, used shrink wrap and pieces of corrugated lying in the path of employees. See our blog “Does Distribution Center Housekeeping Indicates Other Issues?” for more on this subject.

According to the U.S. Department of Labor, tripping, falling and slipping make up most of what it calls “general industry accidents.” Slip and fall accidents make up 15% of all accidental deaths and 25% of all injury claims.

OSHA has issued a rule on Walking-Working Surfaces and Personal Fall Protection Systems “to better protect workers in general industry from these hazards by updating and clarifying standards and adding training and inspection requirements.”

Here is what we recommend you can do to prevent injuries:

- Enact housekeeping standards to pick up all litter

- Keep aisles organized and eliminate congestion from floor stacking

- Immediately clean up spills and loose clutter (peanuts, corrugated, shrink wrap)

- Post signs with placards and caution tape to identify any difference in floor surfaces and steps

- Better illuminate darker areas

Pallet Rack Collapses

A client had a pallet rack collapse from improperly stored cartons of books. It caused a domino collapse of 10 sections of racking. Fortunately, it happened on a Sunday when no one was in the building. Another client had to replace over 15% of the pallet cross beams and uprights in an ecommerce fulfillment center that had been damaged over time by careless forklift operation.

Here are our recommendations:

- Institute a forklift training program and standards that allows you to replace careless forklift operators.

- Walk through your facility and look up to see how uniform pallet rack stacking is. Look for overhanging pallets that might fall or be hit by a forklift.

- Put heavier product away in lower slots.

- Create ample space between racks for forklift operation

- If you can, schedule replenishment and put away at times when employers are not also in common areas

Ergonomic Strain

The repetitive strain of warehouse work creates back, leg and foot injuries. The wear and tear of lifting and bending involved in the work can create lost time.

These are our recommendations for preventing these types of injuries:

- Review workstation design in packing and returns processing. Is the work surface large enough for the work being performed? Typically, we find it’s too small in packing areas and the height of the work surface is uniform, but people are not. Make the surface adjustable to height.

- Provide rubber pads to reduce foot and leg fatigue

- If an operation involves stuffing literature, is there storage for these items, easily within reach?

- Train employees and supervisors how to lift with their legs not their backs.

- Use back braces for heavy lift functions.

Preventing Heat-Related Indoor Illnesses

Some of the ecommerce fulfillment centers we have worked in have been extremely hot in the summer. Certainly, you can’t air condition a warehouse either.

We recommend you look at several things that can lower the work floor temperature:

- Hire a mechanical engineer with expertise in warehouse HVAC systems.

- Are there ways ventilation can be increased to provide cooler air? Can exhaust systems be installed to relieve heat? Are there pipes that can be insulated to reduce heat?

- Provide additional equipment such as pallet jacks to move heavy product around.

No matter how much automation and technology you employ in your ecommerce fulfillment center, healthy employees are key to your success.

Brian Barry is President of F. Curtis Barry & Company